register for newsletter

get latest company news

This is an ordinary T shape baby diapers. Product advantage: basically boundless material loss and low cost. Applicable market: foreign country market. Machine operation: the machine operation difficulty is low, the production station of baby diaper product is less, and this equipment has been very mature.

read more

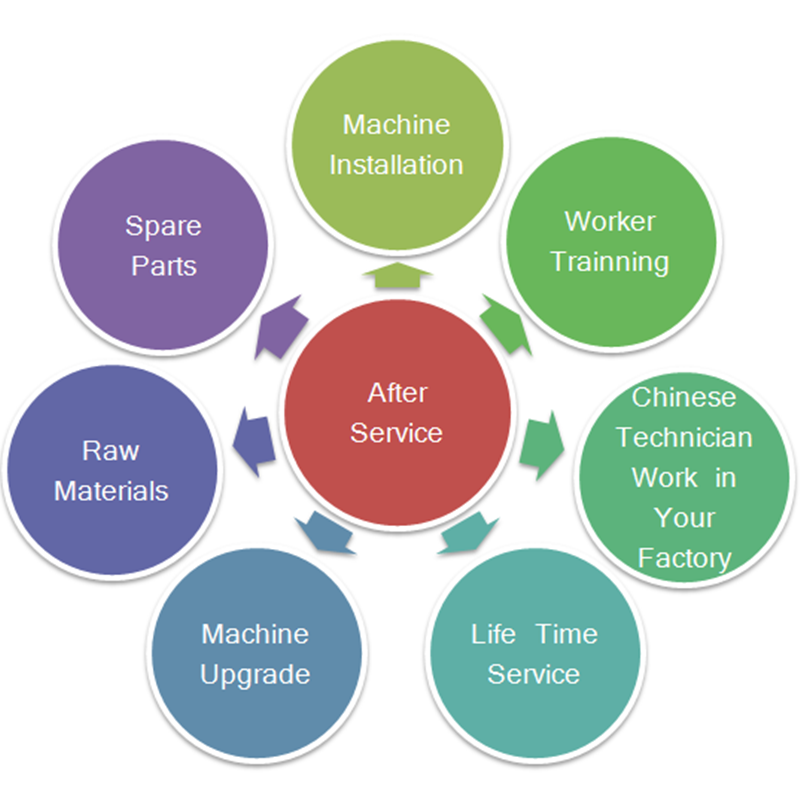

Full Servo High-speed Adult Menstrual Pants Packing Machine Main Technical Parameters of Menstrual Pants Packing Machine Packing Speed 60bags/min Packaging Product(L×W×H) (100-150)×(30-90)×(150-200)mm Packaging Material OPP、 PE、complex film Power Supply 380V/50HZ, 10m²* 5-core power cord Machine Size(L×W×H) 5800*6300*2450 Installed Power 11KW Air pressure 0.5-0.65MPa Weight 9800 Kg This packaging machine is used to pack menstrual pants products, which is a combination of an automatic stacker and two automatic packaging machines, which is capable of completing the bag feeding device, product grabbing, compression, and bag opening, bagging and sealing procedures that are automatically conveyed to the packaging machine, and then remove the cut waste. These sealed products are eventually conveyed along the conveyor belt. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, please feel free to contact us!

read more

Fully Automatic High-speed Underpad Packaging Machine Main Technical Parameters of Underpad Packing Machine Packing Speed 50bags/min Packaging Product(L×W×H) (210-280)×(70-180)×(200-320)mm Packaging Material PE、complex film, nonwoven Bag Thickness 0.04-0.08mm Power Supply 380V/50HZ, 10m²* 5-core power cord Installed Power 24KW Air pressure 0.5MPa Weight 6000 Kg Under the fully automatic operation, this underpad packing machine can complete the process of product grabbing, compression, piece-counting, pushing, bag opening, bagging, sealing, and cleaning tailings. These sealed packages are conveyed along the conveyor belt. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, please feel free to contact us!

read more

Fully Automatic High-speed Baby Diaper Packaging Machine Main Technical Parameters of Baby Diaper Packing Machine Packing Speed 40bags/min Packaging Product(L×W×H) (150-500)×(120-400)×(90-250)mm Packaging Material PE、complex film, nonwoven Bag Thickness 0.04-0.08mm Power Supply 380V/50HZ, 10m²* 5-core power cord Installed Power 25KW Air pressure 0.5~0.6MPa Air Consumption 0.6M³/min Weight 6650 Kg Under the automatic operation of the packing machine, the diapers are stacked neatly through the stacker according to the number of packaged pieces, and then pushed into the compression platform of the packaging machine. When the packaging machine detects the product, it will carry out the process of automatic product compression, conveying and stacking products, bag feeding, suction tape, bag opening, product bagging and other processes. About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

read more

800 PCS/Min Full Automatic Sanitary Napkin Machine Main Technical Parameters of Sanitary Pad Making Machine Item Sanitary napkin production line Output products winged sanitary napkin Control System Full servo / Semi servo / Frequency motor / Economical Part Description Most of the spare parts are under numerical control precisely processing. Key mechanical parts are under CNC processing. Main outsourcing parts are world famous brand. Operation Interface Industry PLC, with humanistic designing and optional collection for production record Certificates CE, ISO9001:2008, SGS Design Speed 1000 pcs/min Production Speed 800 pcs/min Overall Size of Equipment 31(L) * 2(W) * 2.5(H) m Machine Power Approx 240KW (380V, 50Hz) Optional Functions 1. Camera monitoring system (control online size checking, location inspecting, missing inspecting, stain spot scanning and so on.) 2. Material roll auto unwinding servo control 3. Material roll auto unwinding converter control 4. Automatic Packing machine 5. Full-servo control stacker (auto bagging machine) 6. Automatic bagging sealing machine Product Detail Images More sanitary napkin machine About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focusing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram

read more

Disposable Incontinence Hospital Under Pad Machine Main Function Features of Under Pad Machine 1. Single drum former device. Crusher can take both treated and untreated fluff pulp. 2. Fluff pulp feeding is controlled by servo motor. Or air laid paper can be used instead of fluff pilp to produce high quality pads. 3. SAP feeding device. SAP is added mixed with fluff pulp and controlled by servo motor. If use air laid paper to instead of fluff pulp, then SAP feeding device can be used as spare device. 4. Tissue paper double sides feeding units. If use air laid paper to instead of fluff pulp, then tissue paper is unnecessary to use. 5. Net shape pressing device. Cylinder pressing. 6. Fluff core or air laid paper position adjusting device. 7. Fluff core or air laid paper cutting device. Cylinder pressing. 8. Bottom film and top sheet materials feeding units, Glue adding and fixing shape by pressing. 9. Pad vertical folding 10. Wastes rejection device 11. Pad crosswise folding 12. Auto-counting and arrange coming out. (The main machine can link with stacker machine to do automatic packing. ) Under Pad Making Machine Configurations Design Speed 300m/min Stable Production Speed 220-250m/min Start Powerduction Speed 250KW Installed Rated Power 150-200KW Supply Power 380V AC, 50HZ, 3 phase 5 wire ( According to customer) Machine Weight 70Ton Machine Size 25.0m*7.0m*5.0m(L*W*H) Efficient rate ≥ 85% Air 0.6-0.8 M Pa Finished Products under pads and puppy pads Packing Antirust Oil& PE Film Cover & Seaworthy Wooden Box , 2*40HQ Delivery time 120 Days after received the deposit of under pad making machine About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service If you have interest in our product, pls feel free to contact us!

read more

Introducing our "QuickFlow" Sanitary Napkin Machine - the ultimate solution for fast, efficient and versatile production of high-quality sanitary napkins. With its cutting-edge technology and user-friendly design, this machine sets a new standard in the industry. Boasting an impressive speed, the QuickFlow Sanitary Napkin Machine ensures swift production, saving valuable time and increasing productivity. Say goodbye to long waiting hours and hello to an uninterrupted workflow that meets the demands of today's fast-paced world. Not only does the QuickFlow Sanitary Napkin Machine offer exceptional speed, but it also offers unmatched versatility. Whether it's day use or night use sanitary napkins, our machine enables you to effortlessly switch between different sizes to cater to varying customer preferences. Enjoy the flexibility to adapt to market trends and meet the ever-changing needs of your customers. One of the standout features of the QuickFlow Sanitary Napkin Machine is its user-friendly design. Changing sizes has never been easier or quicker. With just a few simple adjustments, you can switch from producing smaller-sized daytime napkins to larger nighttime pads, ensuring a hassle-free manufacturing process. Additionally, our machine is engineered with precision and attention to detail, guaranteeing the production of sanitary napkins that are of the highest quality. Each napkin is crafted with care, ensuring optimal comfort and absorbency, providing women with the confidence and peace of mind they deserve. Invest in the QuickFlow Sanitary Napkin Machine today and experience the revolution in sanitary napkin production. It's time to streamline your manufacturing process, elevate your brand, and meet the ever-growing demands of the market. Don't settle for less when it comes to quality and productivity - choose QuickFlow, the ultimate solution for sanitary napkin production.

brand:

RXitem no.:

RX-BP600payment:

T/T、L/Cproduct origin:

Chinacolor:

Customlizedshipping port:

Xiamenlead time:

120 daysHigh Speed Automatic Disposable Breast Pads Making Machine

|

Designed Speed |

800pcs/min |

|

Stable Production Speed |

600pcs/min |

|

Production Line Center Distance |

300mm(the distance from the material center line to the rack-mounted panel) |

|

Distribution of Raw Material |

top(surface)-absorption layer bottom-cloth like non-woven |

|

The Deviation of Products Weight |

±1.5g |

|

Rate of Finished Products |

≥85% (not including rejected baby diapers at the glue applicator,splicing and jointing material stations) |

|

Production Machine Efficiency |

≥85% |

|

Power Supply |

380V 50HZ |

|

Power Consumption |

240KW (reference)(not including the glue applicator station and the air compressor) |

|

Electric Supply |

380V ± 5%,50HZ, (3 phase,for wire plus ground) |

|

Compressed Air Supply Pressure |

|

|

|

|

|

|

to be defined by customer |

1. Automatic/Full-servo/ Semi-servo system with less worker required.

2. All machining parts are CNC made by our own factory - Quality guaranteed with low repair rate make you a stable production.

3. Applied dumbell device to the Cotton forming system to prevent bandy legs caused, add an extra selling points for your product.

4. Remote assistance dealing with software problem to give you the efficient after-sale service with no production delayed.

5. Professional team with 17 years experience, available to various type & appropriate scheme for different countries (Asia, Mid-east, Russia, India, South Afric etc).

Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team.

More than 15 years experience focussing on hygiene machines.

10 CNC processing machine and 40 other processing machines.

Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on.

Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers.

Fast Female Breast Pads Breastfeeding Pads Machine

Fast Female Breast Pads Breastfeeding Pads Machine

Automatic/Full-servo/ Semi-servo system with less worker required.

Automatic High Speed Servo Baby Pull-ups Machine Manufacture From China

Automatic High Speed Servo Baby Pull-ups Machine Manufacture From China

Automatic High Speed Servo Baby Pull-ups Machine Main Function Features of Baby Pull-ups Machine 1. Full-automatic with PLC control and touch screen; 2. High-speed teeth-like crusher; 3. Web-wheel molding; 4. SAP auto adding with amount control; 5. Servo unwinding,auto-tension control and auto splicing for raw material; 6. Auto reject for wasted & rejected product,auto detect & alarm for material exhausted; 7. Phase adjusting during running without stop; 8. Diaper tri-folding or bi-folding; 9. Diaper auto counting & stacking. Main Technical Parameter of Baby Pull-ups Machine Designed production speed 600 pieces/min Stable production speed 500 pieces/min(or as per customers designed) Machine power three-phase five-wire(380V, 50HZ) Machine capacity about 300-350KW(exclude hot melt applicators and air compressor Machine size 30.0m*7.0m*3.5m(L*W*H)( (Can be customized) Machine weight about 60 Ttons(whole production line) Air pressure 0.6-0.8Mpa Packaging Details: wooden cases and plastic film for full automatic high speed pull-ups making machine Delivery Details: within 120days pull-ups Machine About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

RX-HY600 Semi Servo Type Sanitary Napkin Machine

RX-HY600 Semi Servo Type Sanitary Napkin Machine

RX-HY600 semi servo type sanitary napkin machine is a full auto machine.The finished product comes in two sizes

New Baby Diaper Machine Elastic Waistband Pampers Nappy Production Line

New Baby Diaper Machine Elastic Waistband Pampers Nappy Production Line

New Baby Diaper Machine Elastic Waistband Pampers Nappy Production Line Elastic wasitband baby diaper provides the comfortable waering experience to the baby. The waistband is full with elastic which will not give more pressure to the baby's waistband and give more adjustable space for the side tape. Elastic waistband nonwoven is soft and highly in elastic, the elastic wasitband nonwoven can be formed on line and also can use the ready elastis waistband nonwoven for the production. Main Technical Parameter of Baby Diaper Machine 1. Product Structure Anti leakage N.W.(inside/outside folding),cuff elastic(3+3),top sheet,side tape N.W(inside/outside sperated position) Magic tape (available in winding)ADL,top sheet,regular core+SAP, lower tissue paper, elastic waist,leg elastic(3+3),PE sheet,back sheet,front tape. 2. Product specification S, M, L, XL S length: 390mm, width :320mm Core length:310mm core width:110mm M length:450mm width:320mm Core length :360mm core width :110mm L length:490mm width:320mm Core length :400mm core width:110mm XL length :540mm width :320mm Core length:450mm core width:110mm Will based on last real product 3. Design speed 600pcs/min (M) 4. Stable production speed 500pcs/min 5. Center distance of production line Referring to distance between the center line of product material and main frame plate,300mm 6. Distribution of raw materials The surface layer of the compound surface of non-woven fabric is the core body. 7. Product weight tolerance ±5% 8. Rate of finished product ≥98%(not including the defective products caused by glue applicators, feeding of raw materials and joints of raw materials 9. Efficiency range ≥85% 10. Power 300KW 11. Weight 72T 12. Electric supply 380V±5%,50HZ 13. Dimension 22.3m ×2.3m×3.5m (L×W×M,Include crusher) 14. Air pressure 0.6-0.8Mpa(Buyer need to prepare for air source) 15.Working direction of machine to be decided by buyer 16. Color It depends on customer's requirement Spare Parts of Baby Diaper Making Machine Name of parts Brand PLC Mitsubishi Touch Screen Mitsubishi Servo control drive Mitsubishi Auto web controller BST Bearing use imported bearing NSK/NTN/ Timing belt Gates/Tiger Flat belt Nitta/Tiger Cylinder/magnetic valve Airtac About RX Quanzhou Ruoxin Machinery Co.,Ltd have more than 150 employees. Equipped with Italy and Japan R&D technology team, professional spare parts processing team, assembly team and after service team. More than 15 years experience focussing on hygiene machines. 10 CNC processing machine and 40 other processing machines. Adopting famous and reliable spare parts , like Mitsubishi , Siemens, Sick, Schneider, NSK/SKF, BST, FIFE, SMC,Omron and so on. Turn-key service from start and its long life time service will be offered. Every year we sent more than 100 times technician out all over the world to install the machine or offer service and update the machine for old customers. Factory Processing Map Packing and Packaging Diagram After-sales Service

Fast Delivery High Speed Full Automatic Adult Diaper Machine China Supplier

Fast Delivery High Speed Full Automatic Adult Diaper Machine China Supplier

the making machine for Adult Diaper is equipped with servo motors driving system with PLC control and big touch screen

Fast Speed Wet Wipes Making Machine Production Line

Fast Speed Wet Wipes Making Machine Production Line

unrolling - slitting fabric into lanes - folding - wetting - cutting - pile&counting - delivering

LF-400-ME Diaper Cloth Like Backsheet Lamination Machine(Full Servo)

LF-400-ME Diaper Cloth Like Backsheet Lamination Machine(Full Servo)

LF-400-ME diaper cloth like backsheet lamination machine(full servo) is a professional manufacture hygiene materials machinery.

China Economic Semi-auto Adult Diaper Machine

China Economic Semi-auto Adult Diaper Machine

China economic semi-auto adult diaper machine can make diapers of four sizes.

Copyright © Quanzhou Ruoxin Machinery Co.,Ltd. All Rights Reserved.

friendly links :

scan to wechat