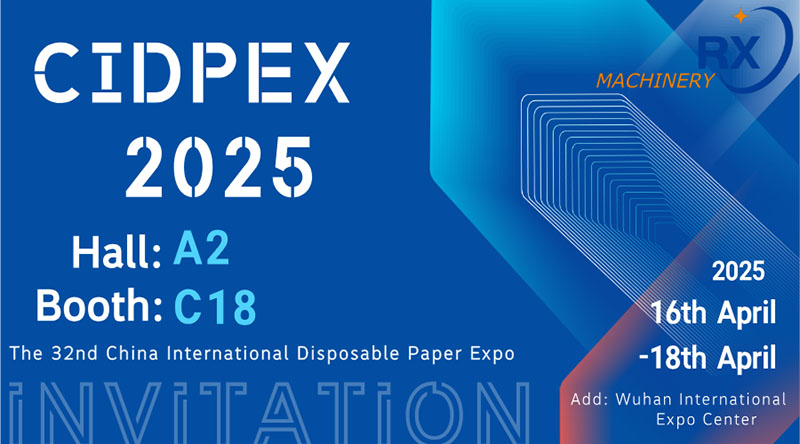

Quanzhou RX Machinery Invites You to CIDPEX2025(The 32nd China International Disposable Paper Expo) – Unlock Smart Manufacturing Opportunities! As an innovative leader in global sanitary equipment exports, Quanzhou RX Machinery Co., Ltd. will participate in CIDPEX2025 from April 16-18, 2025. Visit us at Booth C18, Hall A2 to explore our core offerings: intelligent baby diaper machines, adult diaper machines, sanitary napkin machines, under pad production lines, and more. We will showcase finished product samples (baby diapers, sanitary napkins, adult diapers, under pads) alongside detailed catalogs, providing a "Machinery + Finished Products" one-stop experience for clients and industry partners. Three Highlights – Join Industry Peers at This Premier Event 1. All-Category Intelligent Equipment on Display Witness live videos of our full-series smart production lines for diapers, sanitary napkins, and under pads. Observe high-speed cutting, precise folding, and automated packaging processes that demonstrate high efficiency, stability, and energy-saving advantages. 2. One-on-One Expert Consultations Our seasoned export team will provide tailored technical and commercial guidance, including equipment selection advice, production optimization strategies, and cost-control solutions to help you meet international market standards. 3. Samples & Catalogs for Tangible Insights Experience the tactile quality and craftsmanship of products made by our machinery through on-site samples. Take home our catalogs featuring technical specifications, production capacity data, and application scenarios for all equipment series. Exhibition Details Dates: April 16-18, 2025 Hall: A2 Booth: C18 Venue: Wuhan International Expo Center Contact Now! Tel:+86-15260373015 Email:admin@rxhygiene.com Website: www.rxhygiene.com

read more 0086-15260373015

0086-15260373015 admin@rxhygiene.com

admin@rxhygiene.com English

English فارسی

فارسی français

français русский

русский español

español português

português العربية

العربية Türkçe

Türkçe ไทย

ไทย Việt

Việt